The quality of FPC can be judged from the following aspects:

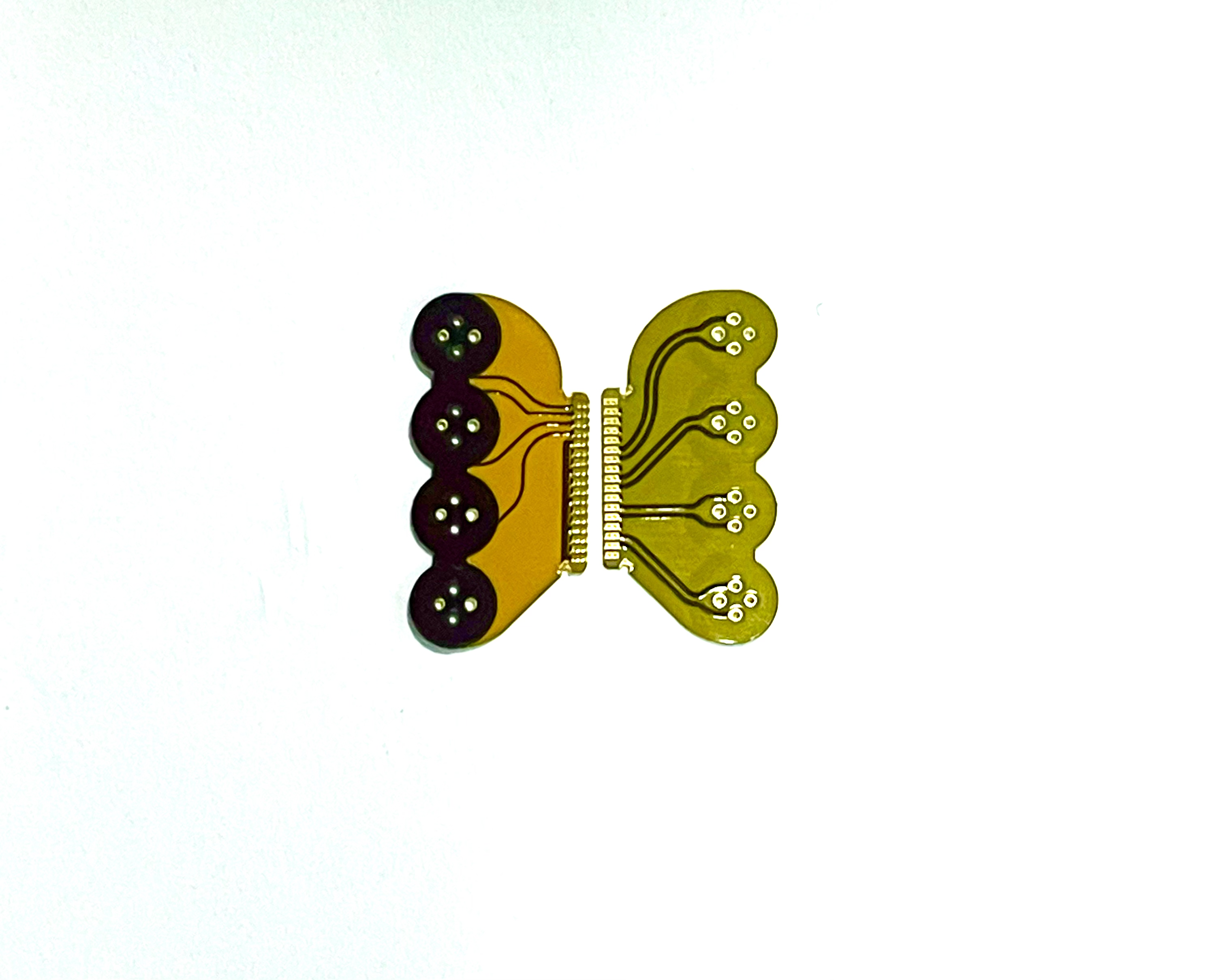

Appearance inspection: Check whether the surface of FPC is flat, smooth, and free of defects such as scratches, stains, bubbles, etc.

Dimensional accuracy: Measure whether the dimensions of the FPC meet the design requirements, including length, width, thickness, etc.

● Conductivity performance: Use a multimeter or specialized testing instrument to test the conductivity performance of the FPC, ensuring that the circuit connection is normal.

● Bending resistance: Fold or bend FPC in half, check if it is prone to breakage or cracking, to uate its bending resistance performance.

● Solder joint quality: Check whether the solder joints on the FPC are full and smooth, and whether there are any problems such as loose soldering and short circuits.

● Material quality: Understand the quality of the substrate and covering materials used in FPC, high-quality materials usually have better performance and reliability.

In addition, reference can also be made to the quality standards and relevant certifications of FPC products, as well as factors such as the reputation and word-of-mouth of the manufacturer. If possible, conducting practical application testing is also an effective way to uate the quality of FPC. It should be noted that the quality requirements for FPC may vary in different application scenarios, and specific uations should be made based on the actual situation.