When referring to "IC carrier board", it usually refers to the substrate or carrier used to install and connect integrated circuit (IC) chips. IC carrier boards play an important role in electronic devices and circuits, providing reliable electrical connections and mechanical support to ensure the normal operation and reliability of IC chips.

Here are some key points about understanding IC carrier boards:

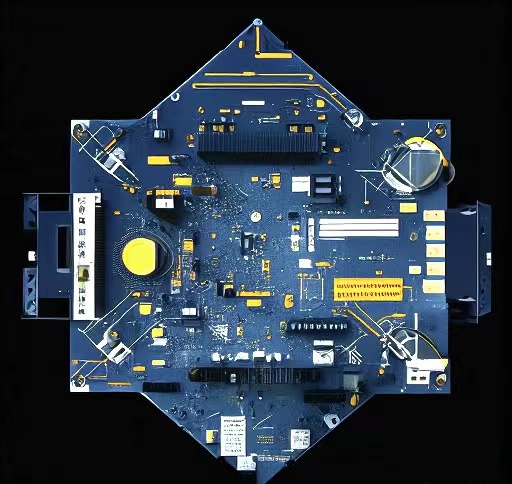

1. Function and function: The main function of the IC carrier board is to provide electrical interfaces and support structures for installing and connecting IC chips. It serves as a platform to provide power, signal, and ground connections for ICs, while also providing stable mechanical support and fixation.

2. Physical characteristics: IC carrier boards are usually made of highly conductive materials (such as copper) to provide good electrical connection performance. The carrier board may also include other layers, such as a layered board or a rigid flex board, to adapt to different needs and application scenarios.

3. Layout and design specifications: The design of the IC carrier board should comply with a series of design specifications and standards to ensure good electrical and mechanical performance. This includes considerations such as reasonable layout, signal integrity, and electrical characteristic matching.

4. Welding and connection technology: IC chips on the IC carrier board are usually connected through welding technology, such as surface mount technology (SMT) or [sensitive word] style technology (through pin [sensitive word] carrier board holes). These methods require high-precision and reliable connections.

5. Protection and testing: To ensure the safety and reliability of IC chips, IC carrier boards usually provide protective measures such as electrical isolation and anti-static protection. In addition, testing and validation are required to ensure that the quality and performance of the entire carrier and IC meet the requirements.

Overall, a correct understanding of IC carrier boards means understanding their functions, design, and manufacturing requirements, and realizing their important role in electronic devices. This can ensure the effective application of IC carrier technology and improve the reliability and performance of the circuit.