When customizing FPC, the following are some details that need to be noted:

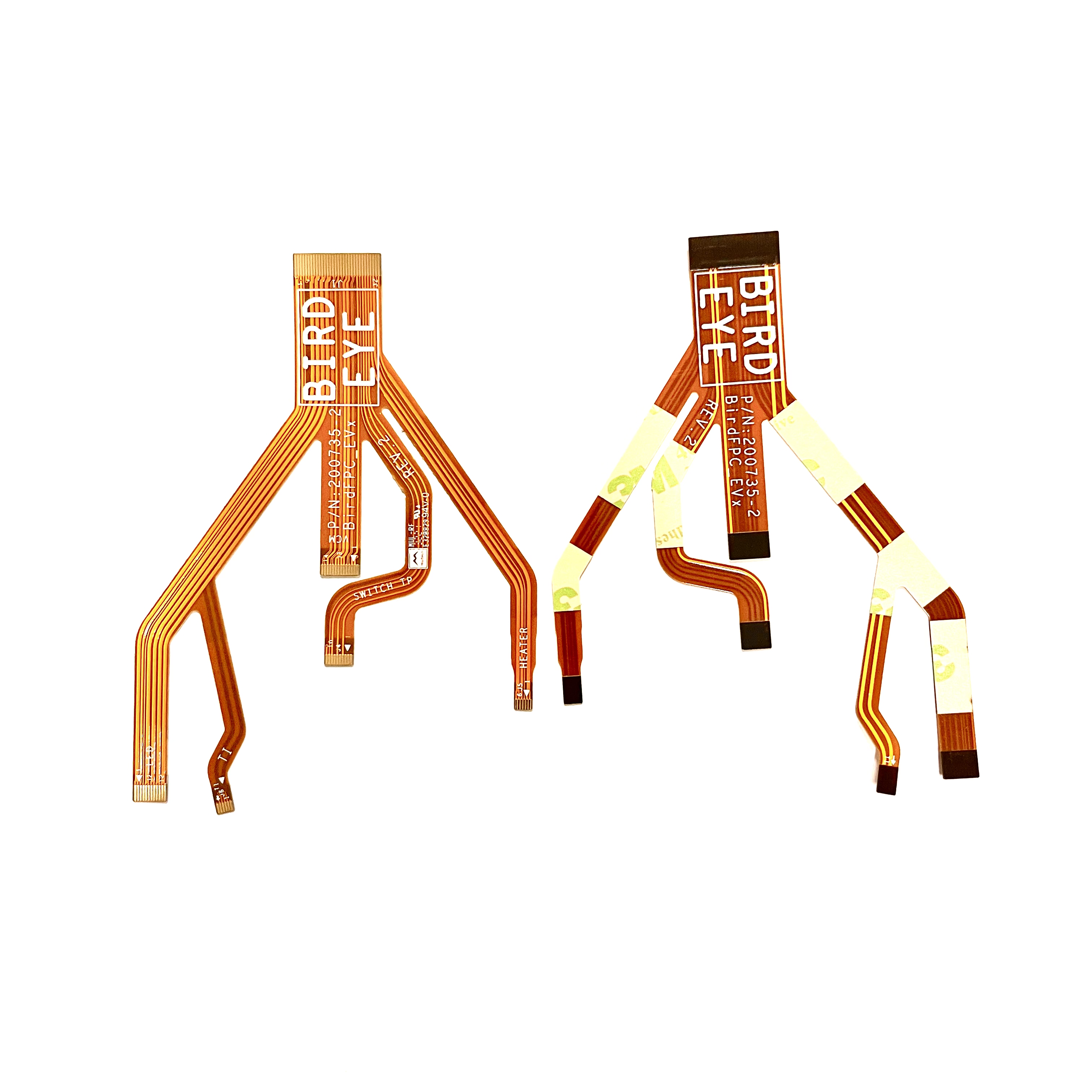

1. Clarify requirements: Before communicating with the manufacturer, clarify your specific requirements for FPC, including size, thickness, number of layers, line width, line spacing, etc.

2. Material selection: Select appropriate substrates, covering materials, and metal conductors based on the product's usage environment and performance requirements.

3. Circuit design: Ensure reasonable circuit design, avoid problems such as overload and short circuit, and consider signal integrity and electromagnetic compatibility.

4. Production process: Understand the manufacturer's production process, such as etching, lamination, drilling, etc., to ensure that it can meet your requirements for product quality.

5. Quality standards: Clarify quality standards and acceptance criteria with the manufacturer, such as conductivity, bending resistance, solder joint quality, etc.

6. Sample confirmation: Before mass production, the manufacturer is required to provide samples for confirmation to ensure that the product meets the requirements.

7. Cost control: Reasonably control costs and avoid unnecessary waste while meeting demand.

8. Delivery time: Determine a reasonable delivery time with the manufacturer to ensure that the project schedule is not affected.

9. Technical support and after-sales service: Understand the technical support and after-sales service provided by the manufacturer to ensure timely resolution of problems encountered during use.

10. Confidentiality Agreement: If there are confidentiality requirements related to the product, sign a confidentiality agreement with the manufacturer to protect intellectual property rights.

11. Packaging and Transportation * *: Confirm the packaging and transportation methods of the product to ensure that it is not damaged during transportation.

12. Communication and Collaboration: During the customization process, maintain good communication and collaboration with the manufacturer, and provide timely feedback on issues and needs.

Customizing FPC requires comprehensive consideration of multiple factors and attention to details to ensure the customization of high-quality products that meet the requirements.