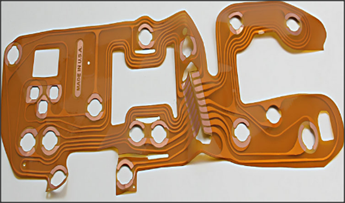

Flexible Printed Circuit (FPC) is a type of flexible circuit board that may differ from other types of circuit boards in the following ways:

1. Material: Soft FPCs typically use flexible substrates such as polyester film, polyimide, etc., while other circuit boards may use rigid substrates such as fiberglass cloth substrates, FR4, etc.

2. Flexibility: Soft FPCs have good bending performance and can adapt to various complex shapes and space limitations, while rigid circuit boards are more difficult to bend.

3. Weight and thickness: Soft FPCs are usually light and thin, suitable for applications with weight and thickness requirements, such as portable electronic devices.

4. Wiring density: Soft FPC can achieve higher wiring density because it can be wired in narrow spaces.

5. Cost: Due to differences in materials and manufacturing processes, flexible FPCs typically have higher costs than rigid circuit boards.

6. Application areas: Soft FPCs are commonly used in mobile devices, cameras, sensors, and other fields that require space and flexibility, while rigid circuit boards are more commonly used in fields such as computers and home appliances.

These differences are not absolute, and specific differences may vary depending on the design, requirements, and application scenarios of the circuit board. The choice between using soft FPC or other types of circuit boards depends on specific design and technical requirements.